MAGMASOFT® 6.0 - MAGMA CC – 连续铸造的模拟

对于金属半成品的制造,连铸工艺至关重要。金属液从中间包或者流槽被引入到一个可以含有石墨嵌件的结晶器中,该结晶器具有短小,快速冷却的特点。金属液在结晶器内的末端会产生稳定凝固的坯壳,并且会以相同的速率从结晶器中被拉出。在开浇前,引锭头会被置入结晶器内的某个位置,当金属液面达到预定位置时,启动引锭头,金属液流也随之变化。

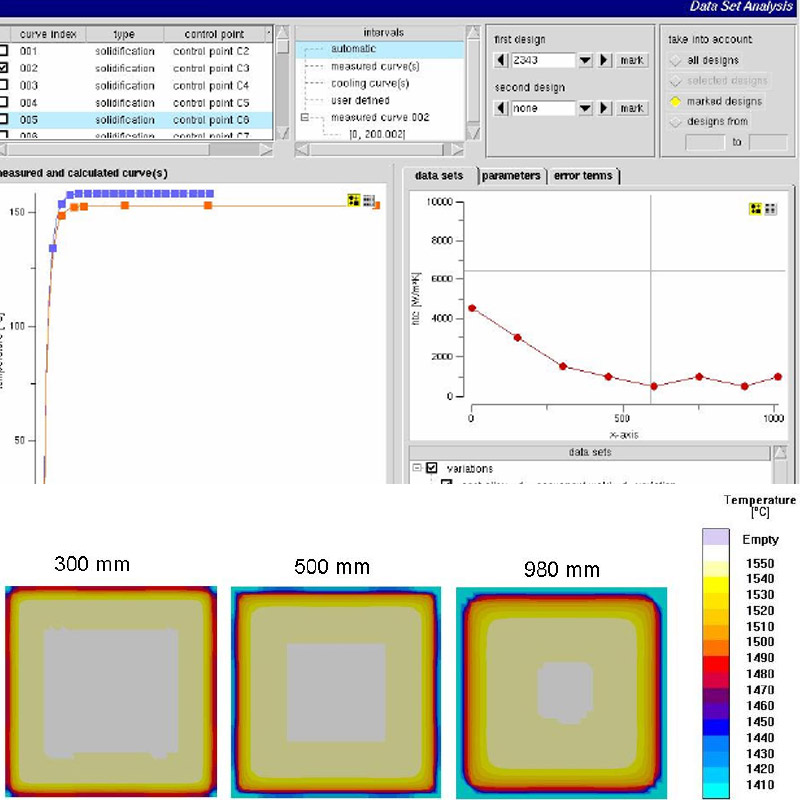

结晶器的初始冷却对于稳定凝固坯壳的形成是决定性的。铸坯会在二冷区域被进一步冷却。对于工艺设计与优化,MAGMA CC是一个充分集成的且与实际相关的交钥匙解决方案,为基于模拟的立式连铸与水平连续铸造工艺优化提供了有意义的信息。

Publication in Area of Continuous Casting

Autonomous Mathematical Optimization of Continuous Casting Processes

Editors:

Wilfried Schäfer, Götz Hartmann, Erik Hepp, MAGMA GmbH, Aachen, Germany

Dieter G. Senk, Sonja Stratemeier, IEHK RWTH Aachen University, Germany

The publication introduces a numerical simulation based optimization strategy, following rigorous thermodynamic and thermo mechanical models as well as a strictly methodic approach.